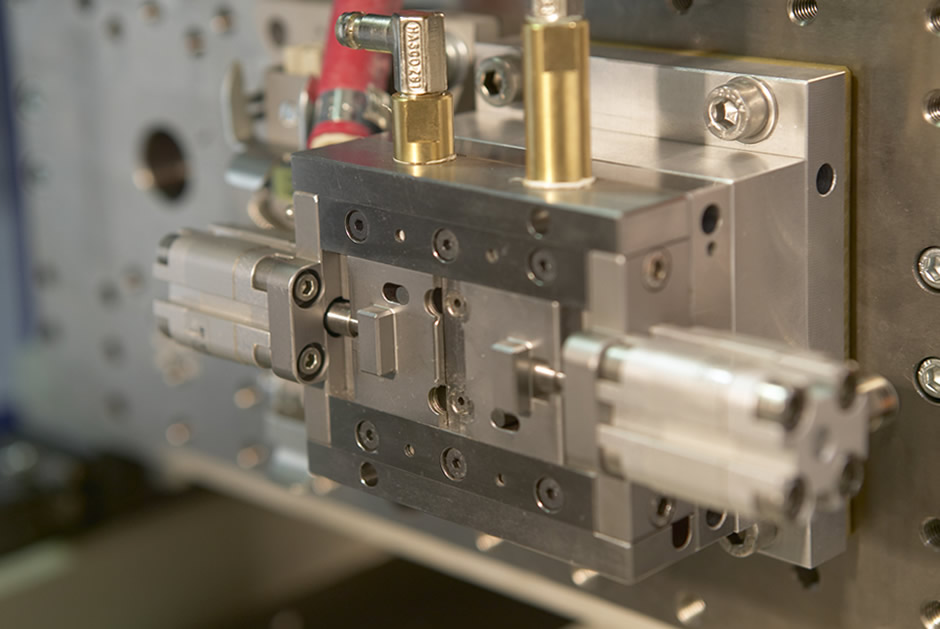

Thermosetting plastic injection molding uses a screw or a plunger to pass the polymer through a heated barrel (120-260 °F) to reduce viscosity and then inject into a heated mold (300-450 °F). Once the material is filled with the mold, it is held in p...

Mold DesignDesigning plastic parts is a complex task involving many factors that address a list of requirements of the application. "How is the part to be used?" "How does it fit to other parts in the assembly?" "What loads will it experience in use?...

Global and China Injection Molding Machine Industry ReportIn 2017, as global injection molding machine market rallied, especially Asian, European and American markets all of which expanded further, the market size also bounced back quickly, with full...

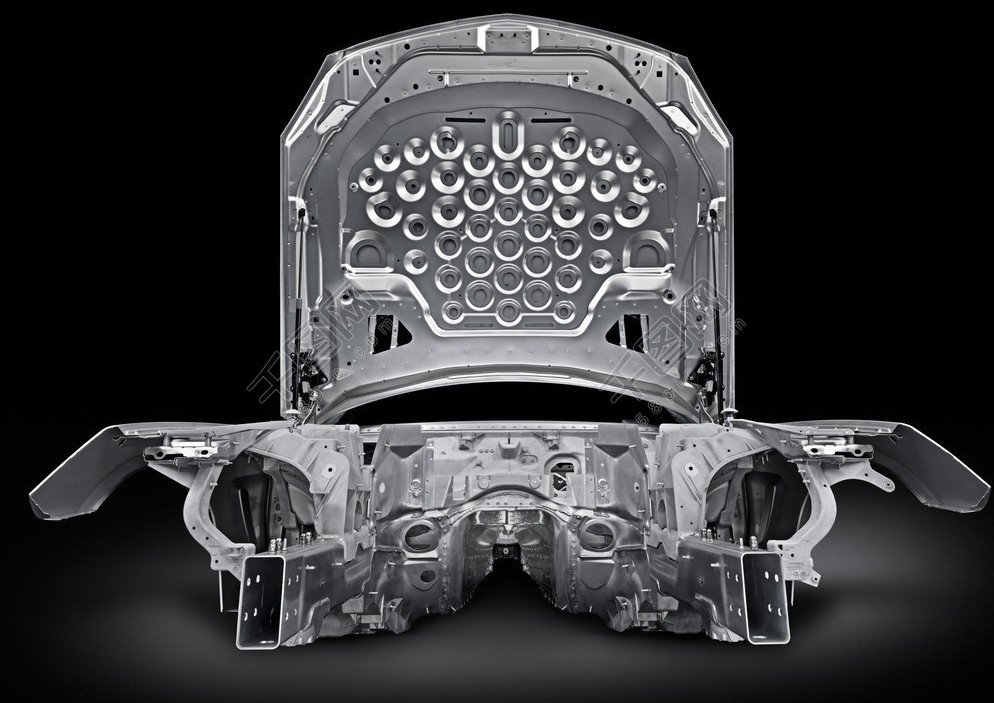

Plastic molding, the wide range of applications of molds,almost all kinds of industries .Molds and tools used in industrial production for injection molding, blow molding, extrusion, die casting or forging molding, smelting, stamping and ot...

China's progressive die industry! In recent years, the development of die casting die industry in China is difficult, but the achievements are gratifying, the overall strength of the industry has also been significantly improved.China's ...