ADTC

ADTC is a manufacturer of plastic molds with the strongest strength and experience [...]

About ADTC

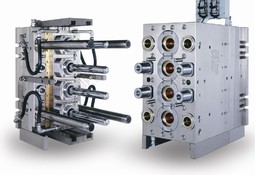

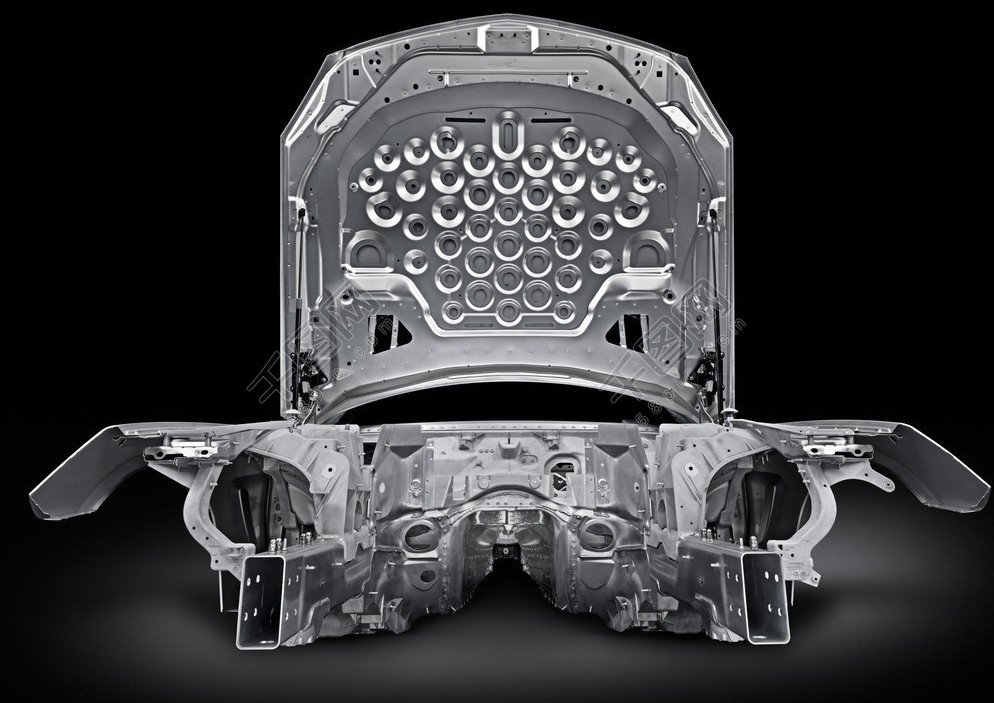

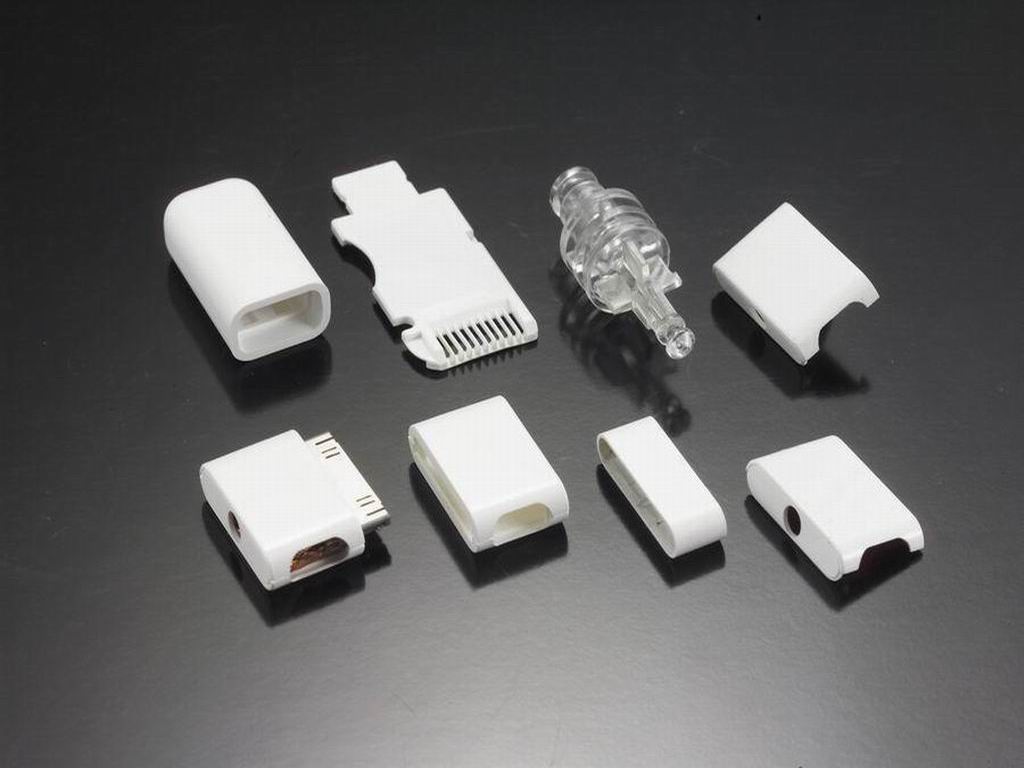

Our factories mold products include common custom plastic molds, high precision molds, high cavitation injection molds,

large sizes molds, two shot molds, unscrewing molds, gas assistant molds, die casting molds,

and now our products range was further enlarged as our Shenzhen factory began offering more products and services such as designing and manufacturing of rubber spray coating,

PCB designing, label making and membrane keypad manufacturing, remote controls, roller and other electronic apparatus.

View more

WE'RE EXPERTS

ADTC is a professional manufacturer of molds, we have professional technology.

WE'RE FRIENDLY

ADTC is a united and friendly team that will provide quality service.

WE'RE ACCURATE

ADTC will give you want most,Don't see what you're looking for?We carry everything.

WE'RE TRUSTED

ADTC must be your most trusted partner,The best quality for the most trusted you

OUR Techonology

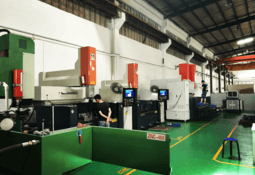

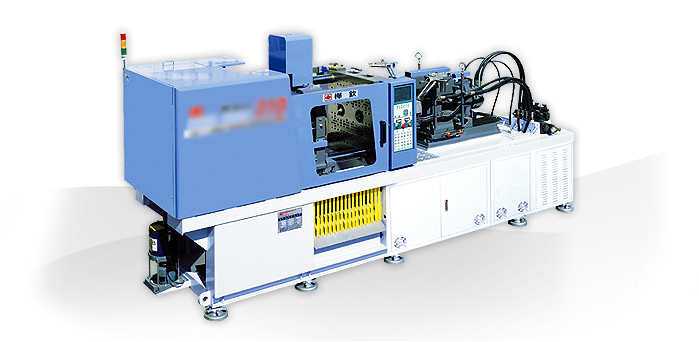

With a decade of hard work and continuous improvement, ADTC hold several big mold factories located in south of China. die casting molds, and now our products range was further enlarged as our Shenzhen factory began offering more products and services

We

provide various injection tools with excellent quality products, we use the

advanced production line, we can deliver the qualified products in the shortest

time. We will provide the best service for our customers.

We export more than 300 sets of molds to overseas each year, and have rich experience in building different kinds of molds

OUR Processes

Our factories mold products include common custom plastic molds, high precision molds, high cavitation injection molds, large sizes molds, two shot molds, unscrewing molds, gas assistant molds, die casting molds ect.

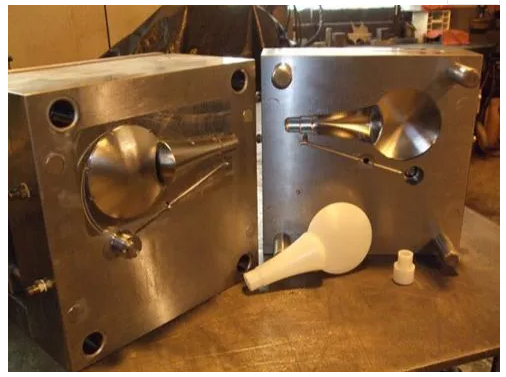

Mold Design

According to the customer’s requirement, our professional engineers will analysis the structure and the technological and the precision of the product make the design.

Mold Manufacturing

Latest equipments will manufacture the mold components, mold components checking-mold base checking-mold insert checking-mold cooling checking

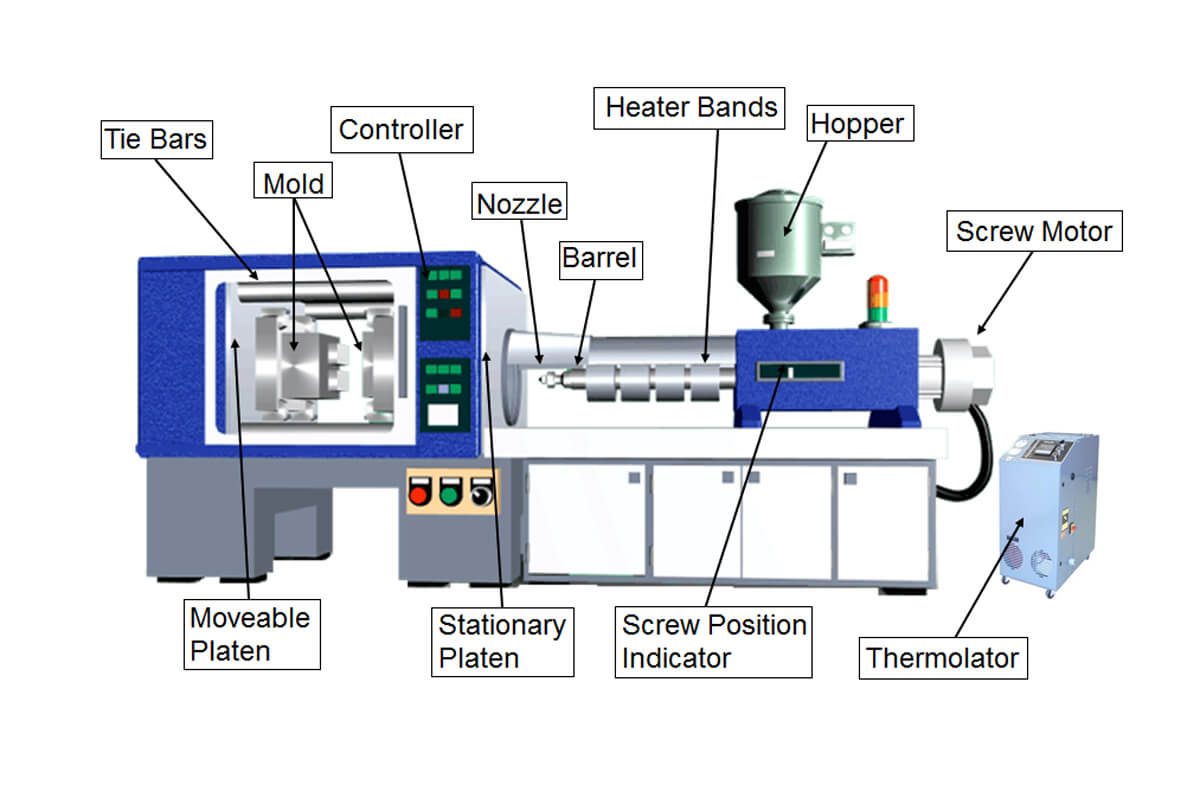

Injection Molding

The propositions behind plastic injection molding process simulation are very basic. First, that although our plastic materials and processes are very complex they are not special. They obey the same laws of physics as everything else and that means that prediction is possible. We will manufacture the good mold an test the performance of the mold.

Quality Management

as an ISO 9001 certificated factory, our factory have a series of dimension and quality checking prior to the mold

shipment as below:

Mold Steel Hardness Inspection

Mold Electrodes Inspection

Mold Core & Cavity Steel Inspection

Mold Trial Report & Samples Inspection

Mold Pre-Assembly Inspection

Mold Pre-Shipment Final Inspection

Export Mold Package Inspection

OUR Products

Latest News

Silicone rubber products have a complete set of complete production processes fr

Injection Molding Machine Introduction Technology: Injection molding is an engin

Global and China Injection Molding Machine Industry ReportIn 2017, as global inj

China's progressive die industry! In recent years, the development of die

1. PS is an amorphous plastic with a wide melting temperature range and good the

The mold industry is a basic industry in the manufacturing industry and the

The injection molds consists of two parts: a movable mold and a fixed mold. The

Exhaust of injection molds is a problem that cannot be ignored in mold design. P

Separate oblique core pulling technology was granted utility model patent,As the

Thermosetting plastic injection molding uses a screw or a plunger to pass the po

.jpg?imageView2/1/w/270/h/180)