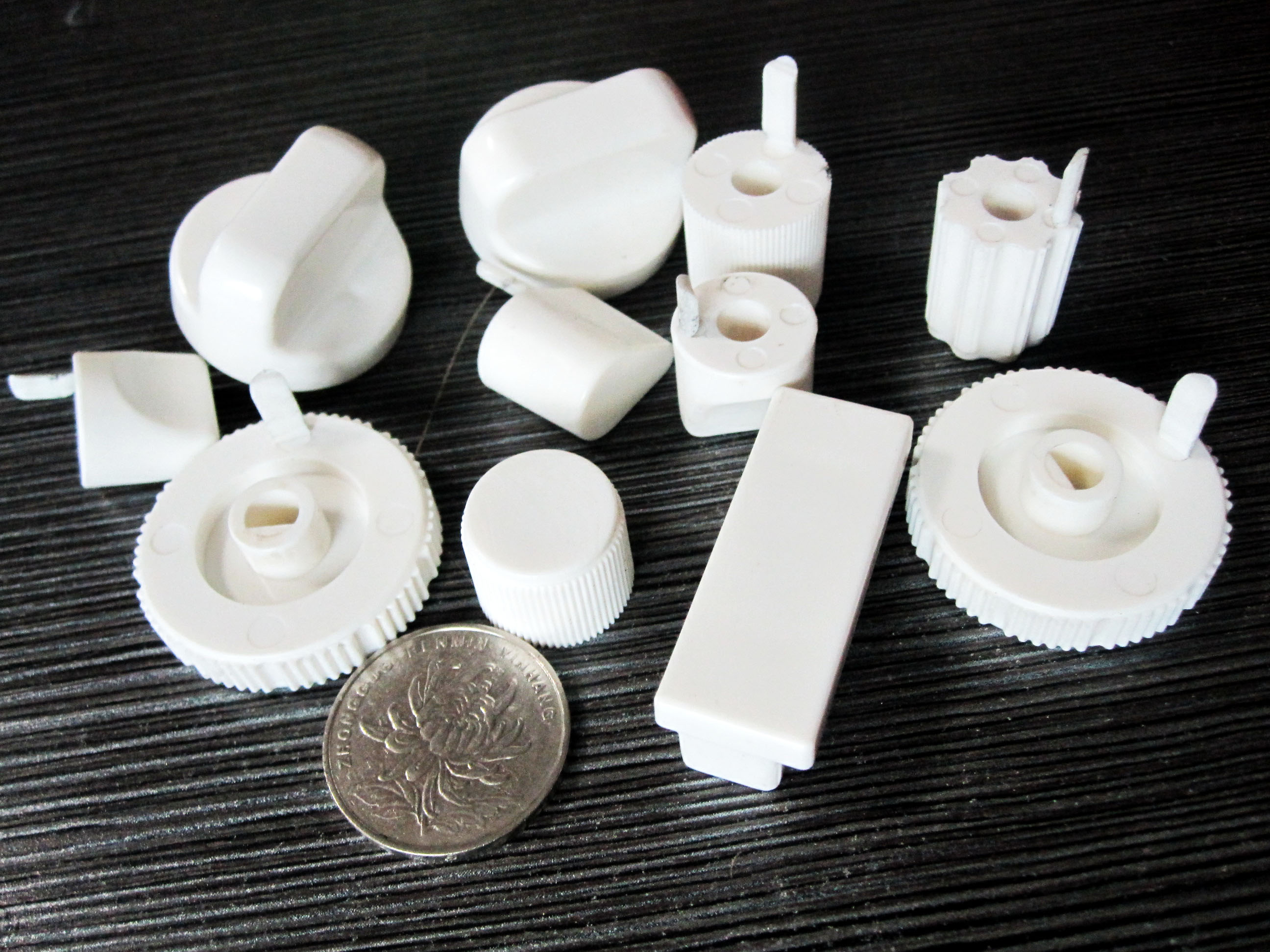

An injection mold is a part that imparts shape and size to a plastic during molding. Although the structure of the mold may vary depending on the type and performance of the plastic, the shape and structure of the plastic product, and the type of the injection machine, the basic structure is uniform. The mold is mainly composed of a casting system, a molding part and a structural part. The gating system and the molded part are in direct contact with the plastic and vary with the plastic and the product. It is the most complicated and most varied part of the mold, and requires the highest degree of smoothness and precision.

The gating system refers to the part of the flow path before the plastic enters the cavity from the nozzle, including the main channel, the cold material hole, the shunt channel and the gate. Molded parts refer to various parts that make up the shape of the product, including moving molds, fixed molds and cavities, cores, forming rods, and exhaust ports. The typical mold structure is shown in the figure.

Mainstream road

It is a passage in the mold that connects the nozzle of the injection machine to the splitter or cavity. The top of the main flow path is concave to engage the nozzle. The inlet diameter of the main flow channel should be slightly larger than the nozzle diameter (O.8mm) to avoid flashing and prevent the two from being blocked due to inaccurate connection. The diameter of the inlet depends on the size of the product, generally 4-8mm. The diameter of the main flow channel should be expanded inward by an angle of 3° to 5° in order to demold the flow path

Cold pocket

It is a cavity at the end of the main channel to capture the cold material generated between the two injections at the end of the nozzle to prevent blockage of the runner or gate. If the cold material is mixed into the cavity, internal stress is easily generated in the manufactured product. The cold pocket has a diameter of about 8-10 mm and a depth of 6 mm. In order to facilitate demolding, the bottom is often carried by the stripper. The top of the demolding rod should be designed as a zigzag hook or a depression groove so that the main channel can be smoothly pulled out during demolding.

Split runner

It is a channel connecting the main channel and each cavity in a multi-slot mold. In order for the melt to fill the cavities at a constant velocity, the arrangement of the runners on the mold should be symmetric and equidistant. The shape and size of the cross-section of the runner have an effect on the flow of the plastic melt, the release of the product, and the ease of mold manufacture. If the flow is of equal amount, the flow path resistance with a circular cross section is the smallest. However, due to the small specific surface of the cylindrical flow passage, it is unfavorable for the cooling of the shunt passage, and the shunt must be opened on the two mold halves, which is laborious and easy to align. Therefore, a trapezoidal or semi-circular cross-section runner is often used and is placed on one half of the mold with the stripper. The runner surface must be polished to reduce flow resistance to provide faster mold filling speed. The size of the runner is determined by the variety of plastics, the size and thickness of the product. For most thermoplastics, the cross-sectional section width is no more than 8m, and the extra large can reach 10-12m, and the extra small is 2-3m. Under the premise of meeting the needs, the cross-sectional area should be minimized to avoid increasing the shunting and prolonging the cooling time.

Gate

It is the channel that connects the main channel (or shunt) to the cavity. The cross-sectional area of the channel can be equal to the main channel (or shunt), but it is usually reduced. So it is the smallest part of the cross-sectional area of the entire runner system. The shape and size of the gate have a great influence on the quality of the product. The function of the gate is: A. Control the flow velocity: B. In the injection, the molten material stored in this part can be condensed early to prevent backflow: C, the molten material is subjected to strong shearing and the temperature is raised. , thereby reducing the apparent viscosity to improve fluidity: D, to facilitate separation of the product from the runner system. The design of the gate shape, size and location depends on the nature of the plastic, the size and structure of the article. Generally, the cross-sectional shape of the gate is rectangular or circular, and the cross-sectional area should be small and the length should be short, which is not only based on the above effects, but also because the small gate becomes larger, and the large gate is difficult to be reduced. The location of the gate should generally be chosen where the product is thickest and does not affect the appearance. The gate size should be designed to take into account the nature of the plastic melt.

Cavity

It is the space for molding plastic products in the mold. The components used to form the cavity are collectively referred to as molded parts. Each molded part often has a unique name. The molded part constituting the outer shape of the product is called a concave mold (also called a female mold), and the inner shape (such as a hole, a groove, etc.) constituting the inner shape of the product is called a core or a punch (also called a male mold). When designing a molded part, the overall structure of the cavity is first determined according to the properties of the plastic, the geometry of the product, the dimensional tolerances, and the requirements for use. Secondly, the position of the parting surface, the gate and the vent hole, and the demolding mode are selected according to the determined structure. Finally, the design of each part is carried out according to the size of the control item and the combination between the parts is determined. The plastic melt has a high pressure when it enters the cavity, so the molded parts should be properly selected and checked for strength and stiffness. In order to ensure the smooth and beautiful surface of the plastic products and easy demoulding, the surface in contact with the plastic has a roughness Ra>0.32um and is resistant to corrosion. Molded parts are generally heat treated to increase hardness and are made of corrosion-resistant steel.

exhaust vent

It is a trough-shaped air outlet opened in the mold to discharge the original and the gas brought in by the melt. When the molten material is injected into the cavity, the air originally stored in the cavity and the gas brought in by the melt must be discharged to the outside of the die through the exhaust port at the end of the flow, otherwise the product will have pores and poor fusion. The filling is not full, and even the accumulated air burns the product due to the high temperature generated by compression. In general, the vent hole can be located at the end of the flow of the melt in the cavity or on the parting surface of the mold. The latter is a shallow groove having a depth of 0.03-0.2 mm and a width of 1.5-6 mm on one side of the die. During the injection, the vent hole does not have a lot of melt oozing out, because the melt will cool and solidify there to block the passage. Do not point the opening of the exhaust port to the operator to prevent the fuse from accidentally squirting and injuring people. In addition, the matching gap between the ejector rod and the ejector hole, the matching gap between the top block and the stripper and the core may be utilized to exhaust.

Structural part

It refers to the various parts that make up the mold structure, including: guiding, demoulding, core pulling and various parts of the parting. Such as front and rear splint, front and rear buckle template, bearing plate, pressure column, guide column, stripping plate, stripping rod and return rod.

Heating or cooling device

This is a device for solidifying and shaping the melt in the mold. For thermoplastics, generally the passage of the cooling medium in the male and female molds, the circulating flow of the cooling medium is used for cooling purposes. The cooling medium to be supplied varies depending on the type of plastic and the structure of the product, such as cold water, hot water, hot oil and steam. The key is high-efficiency uniform cooling, which will directly affect the quality and size of the product. The arrangement of the cooling channels and the choice of cooling medium should be considered based on the thermal properties of the melt (including crystallization), the shape of the article, and the mold structure.

Introduction and composition of injection molds

Plastic products are usually produced in batches or in large quantities. Therefore, molds are required to be used with high efficiency and high quality. After molding, they are less processed or not processed. Therefore, mold design must be considered:

1. Determine the parting surface and gate position according to the performance and molding properties of the plastic parts.

2. Consider the processability in the mold manufacturing engineering, determine the design according to the condition of the equipment and the technical strength, and ensure that the mold is easy to process from the whole to the parts, and it is easy to ensure the dimensional accuracy.

3. Consider injection productivity, increase the number of injections per unit time, and shorten the molding cycle.

4. The size and the structure of the hole, column, convex, concave, etc., which are required to be accurate, are expressed in the mold, that is, the plastic part is not processed or processed less after molding.

5. The mold structure is simple and applicable, stable and reliable, short cycle and low cost, easy to assemble and repair and replace wearing parts.

6. Selection and processing of mold materials.

7. Standardized production of molds: Standard parts such as standard mold bases, common ejector pins, guide parts, sprue bushings, and positioning rings are used as much as possible.

First, the basic composition of the injection mold

1. Gating system: the flow of molten material from the nozzle of the injection machine into the cavity, including the main channel, the runner, the gate, the cold well, and the pulling rod.

2. Molded parts: parts of molded plastic parts, such as cores, cavities and other auxiliary parts.

3. Temperature control system: used to adjust the temperature of the mold.

4. Plastic parts ejection system: including side-dividing mechanism, secondary ejection mechanism, first resetting mechanism, several sequence and fixed-distance division mechanism.

5. Mounting section: A part in which the phantom is reliably mounted on the injection machine.

6. Connection system: The connection system that makes each structural component integral.

7. Guide system: to ensure the movement accuracy of each structural member, such as guide columns, guide slots and so on.

The gating system refers to the part of the flow path before the plastic enters the cavity from the nozzle, including the main channel, the cold material hole, the shunt channel and the gate. Molded parts refer to various parts that make up the shape of the product, including moving molds, fixed molds and cavities, cores, forming rods, and exhaust ports. The typical mold structure is shown in the figure.

Mainstream road

It is a passage in the mold that connects the nozzle of the injection machine to the splitter or cavity. The top of the main flow path is concave to engage the nozzle. The inlet diameter of the main flow channel should be slightly larger than the nozzle diameter (O.8mm) to avoid flashing and prevent the two from being blocked due to inaccurate connection. The diameter of the inlet depends on the size of the product, generally 4-8mm. The diameter of the main flow channel should be expanded inward by an angle of 3° to 5° in order to demold the flow path

Cold pocket

It is a cavity at the end of the main channel to capture the cold material generated between the two injections at the end of the nozzle to prevent blockage of the runner or gate. If the cold material is mixed into the cavity, internal stress is easily generated in the manufactured product. The cold pocket has a diameter of about 8-10 mm and a depth of 6 mm. In order to facilitate demolding, the bottom is often carried by the stripper. The top of the demolding rod should be designed as a zigzag hook or a depression groove so that the main channel can be smoothly pulled out during demolding.

Split runner

It is a channel connecting the main channel and each cavity in a multi-slot mold. In order for the melt to fill the cavities at a constant velocity, the arrangement of the runners on the mold should be symmetric and equidistant. The shape and size of the cross-section of the runner have an effect on the flow of the plastic melt, the release of the product, and the ease of mold manufacture. If the flow is of equal amount, the flow path resistance with a circular cross section is the smallest. However, due to the small specific surface of the cylindrical flow passage, it is unfavorable for the cooling of the shunt passage, and the shunt must be opened on the two mold halves, which is laborious and easy to align. Therefore, a trapezoidal or semi-circular cross-section runner is often used and is placed on one half of the mold with the stripper. The runner surface must be polished to reduce flow resistance to provide faster mold filling speed. The size of the runner is determined by the variety of plastics, the size and thickness of the product. For most thermoplastics, the cross-sectional section width is no more than 8m, and the extra large can reach 10-12m, and the extra small is 2-3m. Under the premise of meeting the needs, the cross-sectional area should be minimized to avoid increasing the shunting and prolonging the cooling time.

Gate

It is the channel that connects the main channel (or shunt) to the cavity. The cross-sectional area of the channel can be equal to the main channel (or shunt), but it is usually reduced. So it is the smallest part of the cross-sectional area of the entire runner system. The shape and size of the gate have a great influence on the quality of the product. The function of the gate is: A. Control the flow velocity: B. In the injection, the molten material stored in this part can be condensed early to prevent backflow: C, the molten material is subjected to strong shearing and the temperature is raised. , thereby reducing the apparent viscosity to improve fluidity: D, to facilitate separation of the product from the runner system. The design of the gate shape, size and location depends on the nature of the plastic, the size and structure of the article. Generally, the cross-sectional shape of the gate is rectangular or circular, and the cross-sectional area should be small and the length should be short, which is not only based on the above effects, but also because the small gate becomes larger, and the large gate is difficult to be reduced. The location of the gate should generally be chosen where the product is thickest and does not affect the appearance. The gate size should be designed to take into account the nature of the plastic melt.

Cavity

It is the space for molding plastic products in the mold. The components used to form the cavity are collectively referred to as molded parts. Each molded part often has a unique name. The molded part constituting the outer shape of the product is called a concave mold (also called a female mold), and the inner shape (such as a hole, a groove, etc.) constituting the inner shape of the product is called a core or a punch (also called a male mold). When designing a molded part, the overall structure of the cavity is first determined according to the properties of the plastic, the geometry of the product, the dimensional tolerances, and the requirements for use. Secondly, the position of the parting surface, the gate and the vent hole, and the demolding mode are selected according to the determined structure. Finally, the design of each part is carried out according to the size of the control item and the combination between the parts is determined. The plastic melt has a high pressure when it enters the cavity, so the molded parts should be properly selected and checked for strength and stiffness. In order to ensure the smooth and beautiful surface of the plastic products and easy demoulding, the surface in contact with the plastic has a roughness Ra>0.32um and is resistant to corrosion. Molded parts are generally heat treated to increase hardness and are made of corrosion-resistant steel.

exhaust vent

It is a trough-shaped air outlet opened in the mold to discharge the original and the gas brought in by the melt. When the molten material is injected into the cavity, the air originally stored in the cavity and the gas brought in by the melt must be discharged to the outside of the die through the exhaust port at the end of the flow, otherwise the product will have pores and poor fusion. The filling is not full, and even the accumulated air burns the product due to the high temperature generated by compression. In general, the vent hole can be located at the end of the flow of the melt in the cavity or on the parting surface of the mold. The latter is a shallow groove having a depth of 0.03-0.2 mm and a width of 1.5-6 mm on one side of the die. During the injection, the vent hole does not have a lot of melt oozing out, because the melt will cool and solidify there to block the passage. Do not point the opening of the exhaust port to the operator to prevent the fuse from accidentally squirting and injuring people. In addition, the matching gap between the ejector rod and the ejector hole, the matching gap between the top block and the stripper and the core may be utilized to exhaust.

Structural part

It refers to the various parts that make up the mold structure, including: guiding, demoulding, core pulling and various parts of the parting. Such as front and rear splint, front and rear buckle template, bearing plate, pressure column, guide column, stripping plate, stripping rod and return rod.

Heating or cooling device

This is a device for solidifying and shaping the melt in the mold. For thermoplastics, generally the passage of the cooling medium in the male and female molds, the circulating flow of the cooling medium is used for cooling purposes. The cooling medium to be supplied varies depending on the type of plastic and the structure of the product, such as cold water, hot water, hot oil and steam. The key is high-efficiency uniform cooling, which will directly affect the quality and size of the product. The arrangement of the cooling channels and the choice of cooling medium should be considered based on the thermal properties of the melt (including crystallization), the shape of the article, and the mold structure.

Introduction and composition of injection molds

Plastic products are usually produced in batches or in large quantities. Therefore, molds are required to be used with high efficiency and high quality. After molding, they are less processed or not processed. Therefore, mold design must be considered:

1. Determine the parting surface and gate position according to the performance and molding properties of the plastic parts.

2. Consider the processability in the mold manufacturing engineering, determine the design according to the condition of the equipment and the technical strength, and ensure that the mold is easy to process from the whole to the parts, and it is easy to ensure the dimensional accuracy.

3. Consider injection productivity, increase the number of injections per unit time, and shorten the molding cycle.

4. The size and the structure of the hole, column, convex, concave, etc., which are required to be accurate, are expressed in the mold, that is, the plastic part is not processed or processed less after molding.

5. The mold structure is simple and applicable, stable and reliable, short cycle and low cost, easy to assemble and repair and replace wearing parts.

6. Selection and processing of mold materials.

7. Standardized production of molds: Standard parts such as standard mold bases, common ejector pins, guide parts, sprue bushings, and positioning rings are used as much as possible.

First, the basic composition of the injection mold

1. Gating system: the flow of molten material from the nozzle of the injection machine into the cavity, including the main channel, the runner, the gate, the cold well, and the pulling rod.

2. Molded parts: parts of molded plastic parts, such as cores, cavities and other auxiliary parts.

3. Temperature control system: used to adjust the temperature of the mold.

4. Plastic parts ejection system: including side-dividing mechanism, secondary ejection mechanism, first resetting mechanism, several sequence and fixed-distance division mechanism.

5. Mounting section: A part in which the phantom is reliably mounted on the injection machine.

6. Connection system: The connection system that makes each structural component integral.

7. Guide system: to ensure the movement accuracy of each structural member, such as guide columns, guide slots and so on.